Q: What are structured cabling services?

Structured cabling is the highway that information travels on in a building. The structure can be large, small, commercial, residential, or a combination.

Structured cabling systems are designed around telecommunications code standards. They define how to lay data cabling in different topologies to ensure flawless continuity and connectivity. Some factors involved in structured cabling solutions include distance limitations, cable types, flammability ratings, and bend radii. These standards are outlined by:

- TIA/EIA-568: The TIA (American Telecommunications Industry Association) and the EIA (Electronic Industries Alliance) issue comprehensive standards covering all aspects of cable installations.

- ISO/IEC 11801 - The ISO (International Standards Organization) and IEC (International Electrotechnical Commission) release material, manufacturing, and testing standards. These standards cover commercial communications: telephony, data, copper, fiber, etc.

- EN 20173: The European standards for structured cabling.

- BICSI: BICSI (Building Industry Consulting Services International) provides best practices around data center design. It complements the previous standards and addresses several subjects not covered by TIA. Most importantly, they issue RCDD (Registered Communications Distribution Designer) certifications.

Why does structured cabling even matter?

It keeps you connected. Most of the technology you use is supported by structured cabling: Wi-Fi, VoIP, DAS, security cameras, audio visual systems, IoT sensors, voice and data cabling, and the list keeps growing. Following standards ensures that these technologies operate as designed when connected.

Structured Cabling Solutions

A structured cabling system represents a standardized and organized approach to designing, implementing, and managing the data cable installation of a network. It encompasses all the physical components, such as cables, connectors, patch panels, wiring, cabling, and related hardware, along with the associated pathways and spaces used for network communication.

Q: Should I use Cat5E, Cat6, Cat6A, or Fiber?

Category 5/6/6A cable, single-mode fiber optic, and multi-mode fiber optic cabling vary in capabilities and price.

Copper cable comes in many flavors, but the most common for structured cabling installations are Cat5E, Cat6, and Cat6. The speed, frequency, and cost increase with each level.

According to TIA recommendations, Cat5E is legacy, Cat6 is the minimum, and Cat6A is recommended for businesses and data centers that require a high level of infrastructure and bandwidth for customers, devices, and others connected to the network.

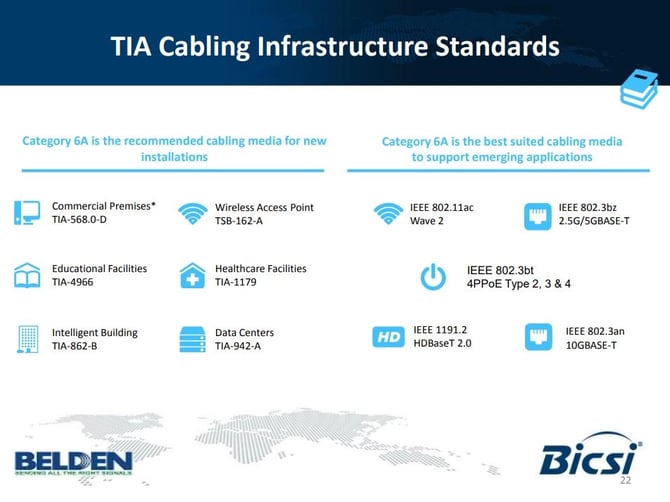

Bicsi and Belden's Cat6A cable recommendations

Fiber cable is divided into single-mode and multi-mode. It's immune to electromagnetic interference, provides more bandwidth, and can be run at longer distances. This extra functionality comes at a cost– installation and material are more expensive.

Most cabling companies recommend Cat6A cable because it offers improved performance and capabilities. Although it has a higher price point, it’s ultimately an investment in your network since it is the most future-proof solution on the market.

- Ideal for high-speed data transmission and bandwidth-intensive applications. It supports data rates of up to 10Gbps over longer distances.

- Supports longer cable runs without signal degradation, making it suitable for larger business needs and network infrastructures up to 100 meters.

- Deploying Cat6A cable future-proofs the network infrastructure by minimizing the need for immediate upgrades and reducing disruptions or downtime.

- Provides support to PoE applications, delivering power and data over the same cable. It ensures efficient power delivery and reliable connectivity for IP cameras, wireless networks, access points, VoIP phones, and more, serving data networks and security systems.

While Cat6A offers superior performance, it may only be necessary for some applications. Factors such as network speed requirements, future scalability, and budget considerations should be considered when selecting the appropriate cabling solutions.

The right cable will depend on how big your facility is and how much bandwidth it’ll need.

Click here for a detailed breakdown of copper vs. fiber optic cables.

Q: Do I need Plenum or PVC?

Using plenum or PVC (Polyvinyl Chloride) cable comes down to your building’s HVAC system.

Plenum cable is designed to operate in a “return air” space. Typically these spaces are above a suspended ceiling or beneath a raised floor. They are a “return air” space because it's where HVAC systems get the air to heat or cool.

Plenum cable is more expensive than PVC because of the less flammable compounds used in production. The cable must pass a burn test that measures flame spread and smoke emissivity when exposed to a flame of a certain intensity and duration. When plenum burns, it puts off less poisonous gas. Alternatively, PVC releases hydrochloric acid and dioxin as it burns.

If ever in question, the building inspector is typically the AHJ (authority having jurisdiction). An inspector can help you with the nuances since plenum cable may be recommended in certain areas even if the code doesn't require it.

Q: Do I need 1 or 2 data cables per work area?

This decision is a widely debated topic. The fact is cable is low maintenance and inexpensive relative to the entire telecommunications system and structure that it serves. The increased functionality and bandwidth from one more data cable can be priceless. However, going back and adding cables and wiring can be expensive and cumbersome, especially after the drywall is in place. Due to the cost and complications of adding cables later, we recommend installing all low voltage wiring during the initial construction.

TIA/EIA-568-B.1 advises two drops per work area. Stating, “This Standard recognizes the importance of both voice and data telecommunications in a commercial building. At least two telecommunications outlets/connectors shall be provided for each work area. Consideration should be given to installing additional outlets/connectors based on present and projected needs.”

Q: Should I compare Mhz?

Manufacturers design and test their cables to perform at specific frequencies depending on the applications intended to run over them. Category 6, for example, is designed to be tested up to 250Mhz and provide a positive signal-to-noise ratio out to that frequency. This capability enables gigabit ethernet to run as intended over the cable with an acceptable amount of packet loss. Cat 5e, on the other hand, was only designed to 100Mhz.

One should not get caught up in manufacturer claims of “tested to 350Mhz vs. 400Mhz”. The real question is, “What is the signal-to-noise ratio at the frequency of the system you are running.” You can test a barbed wire out to 1000Mhz, but it's still barbed wire.

Q: What are test results about, and why do they matter?

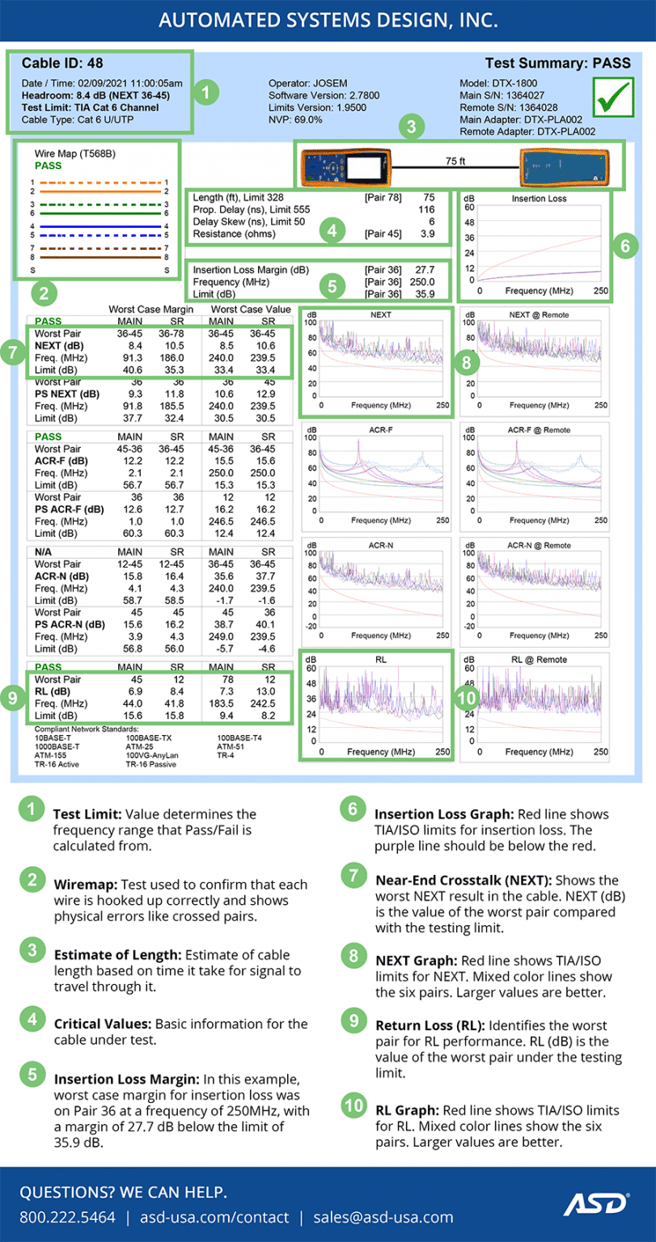

Test results are an integral part and commonly required on structured cabling jobs. The installer can use a handheld tester to plug into the network and test each cable for factors like wire map, distance, cross-talk, and ACR (signal to noise). After project completion, these tests are downloaded into a file and handed to the owner. Test results verify that the system installation meets industry standards and that terminations were done correctly.

A Fluke tester is the most common and supports TIA and ISO specifications for Cat5E and Cat6 cables. It provides Pass/Fail results. The example below goes over how to read standard fluke test results.

Click on the image to download it as a PDF.

Q: What's the industry standard for a warranty?

Cabling system warranties eliminate confusion between the cable manufacturer and the connectivity manufacturer if the system has a problem. In the early days of structured cabling, there was mainly one cable and connectivity manufacturer. Many companies now have legal agreements to support a single solution and warranty design.

Most connectivity and cable companies will tout a 25-year warranty. Truthfully, if the cabling system works after the contractor tests it, it should last every bit of 25 years. The exception is if someone does something to the system that materially alters or changes it. The electrons will not “quit working” one day. ASD® is proud to offer a lifetime warranty.

Q: What should the end deliverable be for a structured cabling system?

When properly designed and installed, the end deliverable should be a structured cabling system that supports the customer’s needs now and well into the foreseeable future. The MDF (Main Distribution Frames) and IDF (Intermediate Distribution Frames) should be well thought out, and cables should be neatly dressed. It should have additional cable runs that support a wireless overlay and have sufficient bandwidth in the backbone to handle a step-change in bandwidth needs.

For the last 20 years, clients have utilized more bandwidth in the current year than the previous year, and this trend shows no sign of slowing down. We've never heard anyone say, “We put in too much cable.”

Q: What should I budget for my structured cabling project?

Although this is our last question on the list, it's often our first question. Unlike most vendors, we welcome this question and like to provide helpful information. From a rapid ballpark estimate to more detailed pricing based on your specific needs, contact us for a free estimate. In the meantime, learn more about pricing with our free Structured Cabling Purchasing Guidebook.

Editor's Note: This post was originally published in October 2017 and has been updated for freshness, accuracy, and comprehensiveness.

Leave a Comment