Client

Dollar General began its DG Fresh initiative to expand its portfolio and include fresh grocery products. It is such a success they’re having to build additional distribution centers across the United States that have cold and freezer storage. They needed a vendor who could design and build a reliable infrastructure in their demanding warehouse environment.

Challenge

The DG Fresh distribution centers are well over 500,000 sq. ft. and include office space, refrigerator, and freezer storage. The cold temperatures require additional planning to keep the wireless infrastructure functioning and at the manufacturer recommend temperatures. The extreme temperature challenge, coupled with the sheer size of the facility, made this an exciting project.

IMPORTANT CONSIDERATIONS

- What steps must be taken to keep all of the equipment up-and-running, even in 10-degree temperatures?

- Considering the size of the facility, how much fiber will be required?

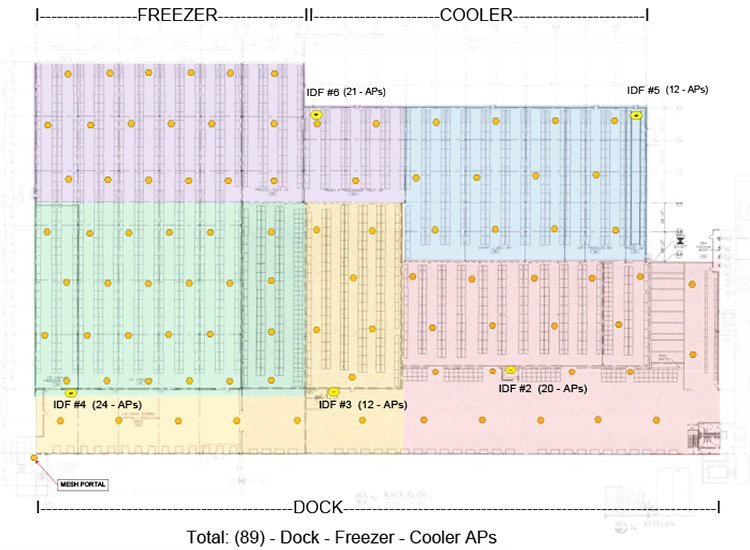

- How many access points are needed to ensure flawless connectivity?

|

|

|

Solution

The distribution centers are all laid out similarly with an MDF, 5-7 IDFs, and single-mode armored fiber run to connect them. In the cold storage areas, special low-temperature cable was used, and IDFs had heaters inside them to keep the switches warm. iCAT-ITS Cat6 cable was used everywhere except the freezer storage. Each facility has approximately 150 wireless access points so that items can easily be tracked when they’re pulled, moved, and loaded on trucks.

|

Result

When dealing with fresh and frozen food, time-management is of the essence to ensure you’re getting produce and perishable items in front of the consumer as quickly as possible. That all begins with an efficient distribution center. By providing a reliable wireless network throughout the facility, the DG Fresh team can receive, process, and ship orders easily. Dollar General customers are taking notice too; the DG Fresh initiative has already proven to be a success and is rapidly expanding. ASD® has completed four distribution centers this year in Georgia, North Carolina, Montana, and Indiana, and to keep up with demand Dollar General has scheduled seven more centers for next year.